The World of Wool Spinning Mill Blunck

Completely hidden - in a backyard in Bad Segeberg - is a real treasure. As soon as you step through the door of the old clinker building, you find yourself on a journey through time, a journey into the world of the former Blunck wool spinning mill. In future, this journey will be made accessible to everyone. The old wool spinning mill is on its way to becoming a museum!

Joachim Christian Blunck founded the wool spinning mill in Bad Segeberg in 1852 to process wool only from the region and without gas or electricity, this was no way an easy undertaking. In the beginning, the workplaces were lit with oil lamps; the company had to build its own wells, as the town did not have central drinking water supply until 50 years later. The first machines were driven by horse-drawn carriages, a few years later these were replaced by steam engines. This enabled the spinning mill to continue to develop and was kept going as a family business.

However, economic boom, technical progress and rapidly changing consumer demands after the Second World War changed the demand for hard-wearing wool products immensely. The garment industry was increasingly outsourced from other countries and sales figures steadily declined. In the beginning of the 2010s, manufacturing and active operations were gradually discontinued.

After 169 years, the Blunck wool spinning mill was finally deregistered from the commercial register.

TIME STANDS STILL

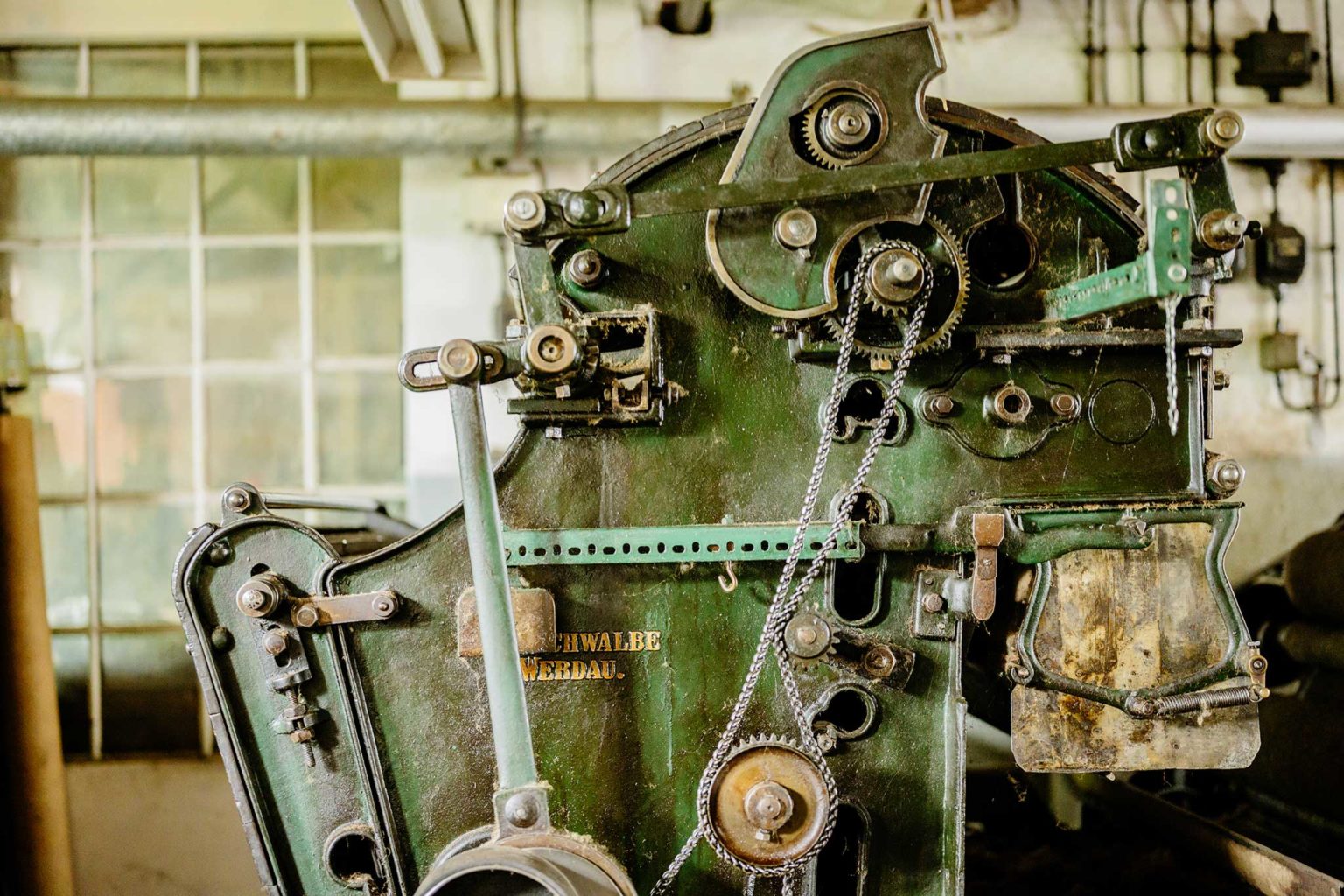

When you enter the spinning mill you get the feeling that the employees went home last night and were to return for the next shift in the morning. Apart from the layer of dust on everything it doesn't look like a shut-down production or a non-profitable business. A museum is planned in which the entire production process can be experienced, and the machines are actively demonstrated from time to time. A museum has been planned where the machines will be turned on for demonstration purposes where the entire production process can be experienced.

Our tour begins in the washing room where you will find the now decommissioned steam boiler; it was used to generate hot water - with the help of hard coal - to wash the raw wool delivered to the mill. Right next to it is the large dyeing boiler, which was also powered by steam. In the past, there was a self-sufficient system here with a boiler house. Energy, heat, hot air - everything was there, and it worked. But this is no longer feasible today, because you have to ensure a certain level of dryness into the building, especially in the winter months.

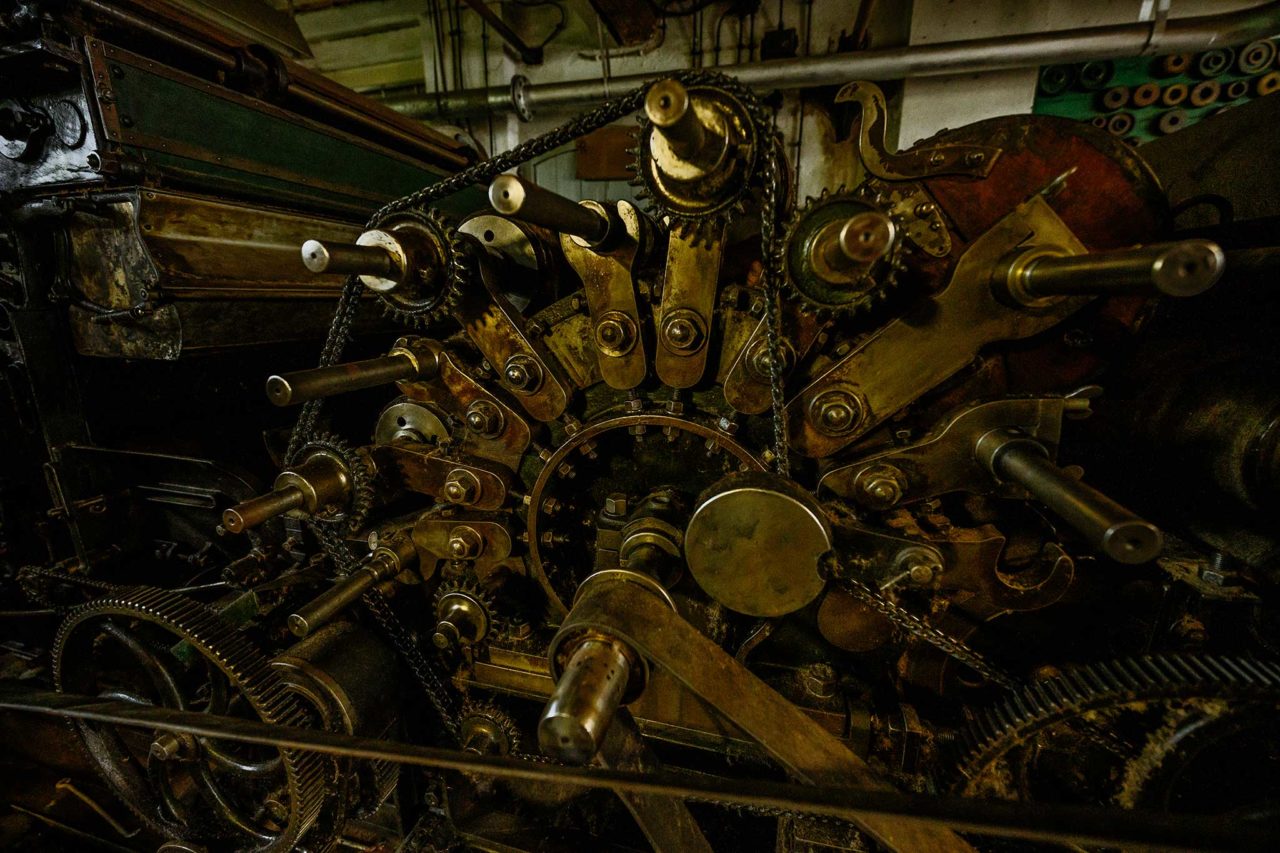

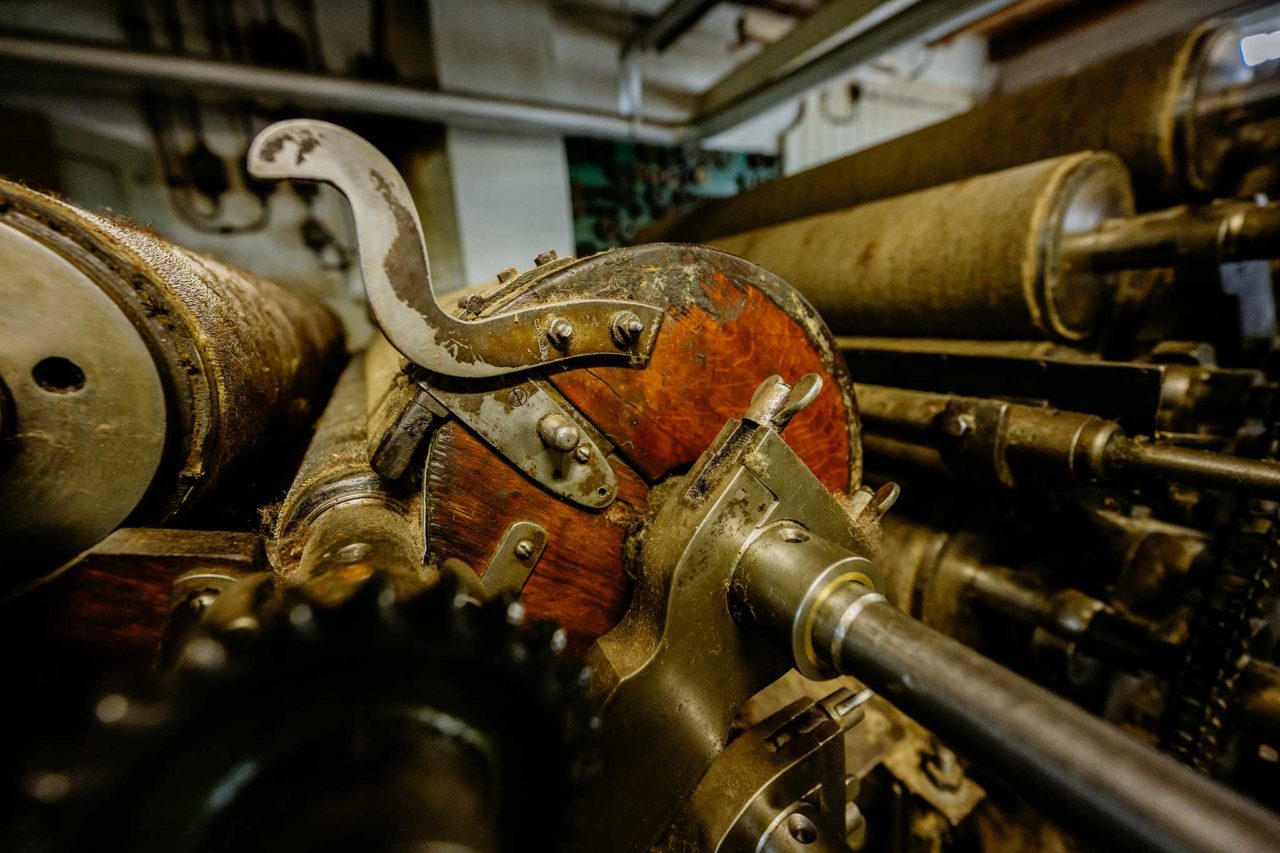

In the next room we come across the grinder which is used to loosen the wool and clean the coarse dirt. The wool flakes are conveyed through several rollers with large steel teeth running against each other and gradually defiberizing them. This renders the wool as optimally prepared for carding and spinning.

A small winding path leads us to a large working room on the first floor. It must have been quite busy here when all the machines were running at the same time. Up to 30 employees worked here in the spinning mill, there were eight women in the knitting department alone.

The next step, pre-treated wool comes out of the mincer onto the carding machine and passed through a large number of counter-rotating rollers fitted with steel needles in the direction of travel. This created a light wool pile which was further compressed by following squeezing and folding operations. The pile divider then finally divided the pile into uniform strips and rubbed them into windable yarns. The so-called roving was wound onto rollers so that it could be further processed in the spinning mill.

The old wooden staircase leads us to the upper floor which creaks underfoot. With every step you can feel the many stories that have taken place in this building. In every corner you discover small details that reflect the love of working with wool and you realize how much passion was put into crafting here every day.

And then the room opens, and we are standing in front of the spinning machine, which extends over the entire second floor. With its length of 24 meters and 320 spindles, it is a real feast for the eyes. The spindles all had to be wound and staked by hand pinning process with single-thread yarn took about 2 hours. One had to keep adding rollers and tying threads indeed, everything was done by hand. The machine was very sensitive and therefore prone to failure, and it could only be operated with a great deal of experience. Its longevity depended on the conscientiousness of the operator.

THE END PRODUCT

Depending on the purpose for which the yarn was to be used later - whether for knitting, hand weaving or felting - it was twisted even further, dyed or bleached if necessary and prepared for sale. A look into the warehouses left our mouths agape! The shelves are still full to bursting with hundreds of kilos of finished knitting and carpet yarns. The moths have had truly paradisiacal conditions here for the last 10 years.

Well hidden behind the spinning machine is the door to the knitting mill. They not only produced and sold the yarn, but also made products like knitted wool socks, shafts and much more right here in-house and offered them for sale in the attached little shop at the front.

"THE BUSINESS WAS CLOSED DOWN BECAUSE MOST OF THE PEOPLE WHO WORKED HERE WERE ALREADY OLD.THE NEW GENERATION, WAS NOT ENCOURAGED TO TAKE OVER THE BUSINESS. BESIDES, IT'S CRAMPED AND NOISY HERE; YOU HAVE TO LIFT HEAVY THINGS. NOBODY WANTS TO DO THAT ANYMORE. ALL PEOPLE HAVE BECOME SO COMFORTABLE."

WHAT HAPPENS NEXT?

In the last few years, a support association has been founded, a lot of money has been raised and the network has been expanded so that renovation and repair of the building can begin soon. You can support the descendants of Joachim Christian Blunck in many ways.

- Become a member of the Friends.

- Book a guided tour of the wool spinning mill.

- There is a desperate need for skilled workers who can maintain and operate the machines. People who would like to help with the preparation of the museum material or contribute their talents and labour in all possible areas. Contact them directly via their website.

"The purpose of this museum is to show how a spinning mill used to look and function. How people used to live, how they lived in the smallest of spaces. To make it tangible."